- ISO 2768 consists of the following parts, under the general title General tolerances: Part 1: Tolerances for linear and angular dimensions without individual tolerance indications - Part 2: Geometrical tolerances for features without individual tolerance indi cations Annex A of this part of ISO 2768 is for information only.

- DIN ISO 2768-2 is for simplifying drawing and fixes general tolerances in three tolerance classes for form and position. By choosing a special tolerance class exactly the precision level common in workshops should be taken into account.

Iso 2768 Hole Tolerance Table Top

I have some drawings from Germany that use the DIN 2768 tolerances and I am having trouble understanding it correctly. I do not have a full copy of the DIN but I do have some notes and a brief discription of how the tolerances are supposed to work but I still dont quite understand it.

The parts are shafts and couplings and have to fit bearings so I know some of the tolerances are going to be plus and some are minus. Could anyone offer a simpler explaination of what I am seeing.

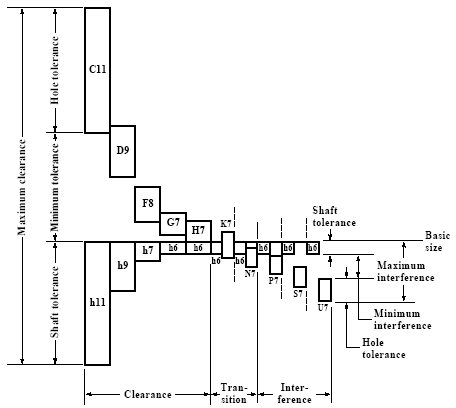

One of the external shafts has a f9 while most of the other shafts have a h9 or h6. A keyway has a N9 and the internal keyway has a j59. One of the internal bores has a M6. Most of the tolerances use lower case but some are upper case, I dont know if that makes a difference or not.

Anyone know of a source for a simpler explaination of these that is in english?

Charles

Iso 2768 Tolerances

Chinese stealth armor new vegas. ISO2768 has a sliding tolerance based on the size of the dimension. For a medium tolerance class per the ISO, dimensions over 6mm but up to 30 mm have a tolerance of +/.2mm. Dimensions above 120 but up 400 have a tolerance of +/.5mm. Astra adt40 manual. Therefore, the 200 dimension would have a tolerance of +/.5mm.